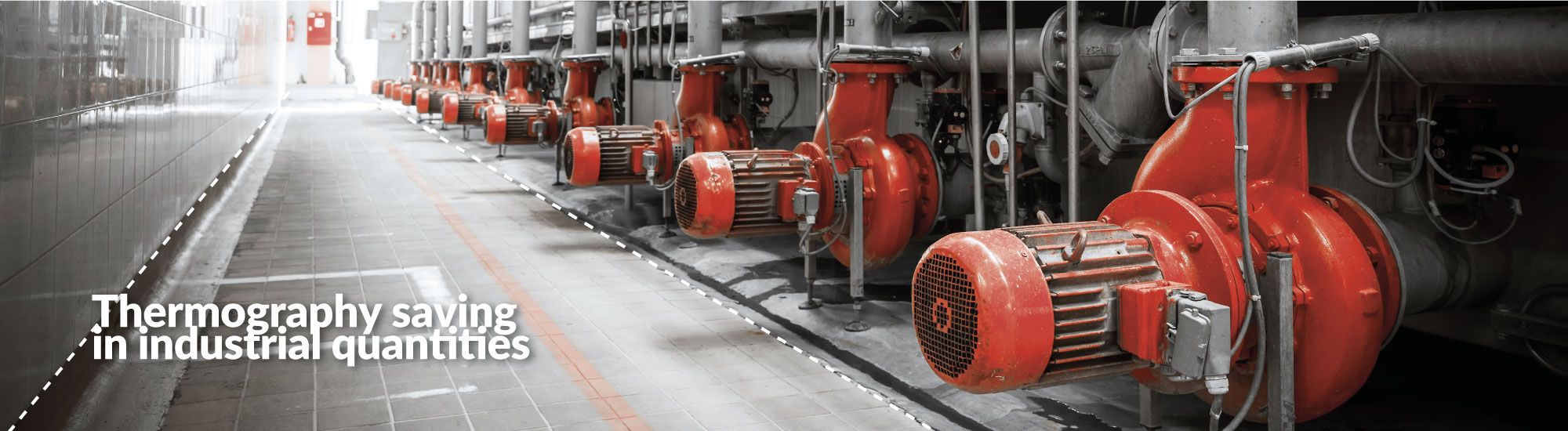

anticipate to the Error

Our ELECTRO-MECHANICAL THERMOGRAPHY tools are are directed to manufacturers and users of industrial environments, providing the ability of Analyze, Certification, Prevention and Thermal Prediction, so you can see failure or lack of quality before they occur.

Thermographics PLANE

Guide for your maintenance personnel

Like the electrical drawings, mechanical, pneumatic, thermal plane is necessary to check the state of origin of panel and machines. Easy to interpret for the current maintenance personnel; documentation and quick overview of the proper values of temperature; facilitates revisions without resorting to expecializado staff

Thermographic Certificate

The most simple and economical of the three services

Abnormalities contacts are detected (Oxide, loose, molten), Overload (intensity, phase unbalance), power quality (transients, harmonics), thermal management (ventilation, cooling, resistors, electronic, radiators), mechanics (in joint engine and pulleys, chains, gears, bearings, cams .. .)

ThermoKontroI SM

Reviews and analysis of thermal deficiencies

Analyzes the technical part. And it helps in the management decision-making. In each deficiency is analyzed: the limits of the machine, the level deficiency, the charge level, the probability of failure, risk assessment, the consequences, the risk involved, risk reduction, the level of intervention, implementing mitigation measures; recommendations.

Do you want to collaborate with us?

Thermography, oriented to measurable objects

1. Do not interrupt the production of your company.

2. Predicts problems in your production process.

3. Save on maintenance and extends the life of your machinery

4. Energy consumption more responsible and sustainable.